Malvaney recently brought to my attention some very cool photos of the inner bowels of the Washington County Courthouse that have been made available on the MDAH HRI database.

These images show the metal lath that supports the plaster in the courtroom. Our conversation quickly turned to pondering when this metal lath might date to, and how extensively was the courtroom remodeled in the 1930 work overseen by James Spain? We ruminated between the thoughts that the metal lath implied the 1930 work actually gutted the courtroom completed to the studs, and the possibility that the metal lath actually date to the 1891 construction.

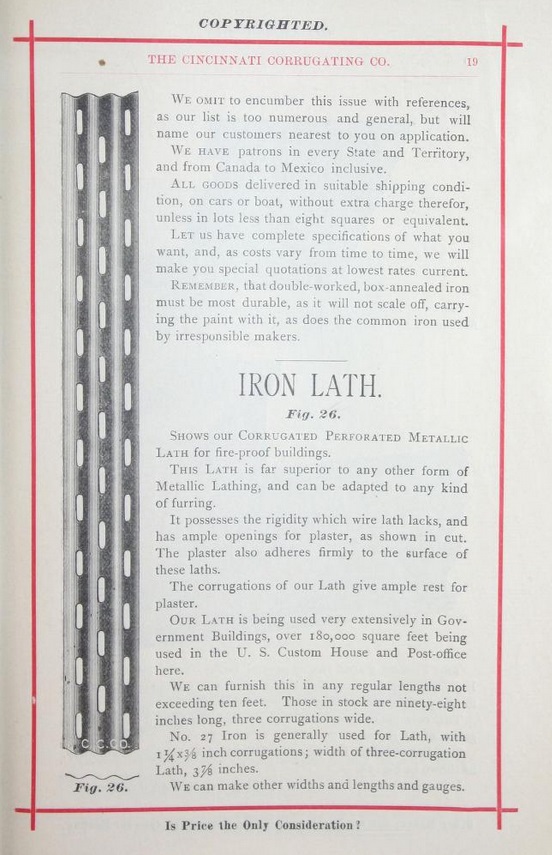

While the first metal laths were patented in 1797, modern metal lath dates to the late 19th century.[1] Its creation arose from the need to fireproof buildings by eliminating wood components, in this case it was replacing wood lath with metal. Metal lath use really took off in the late 1870s when iron and later steel production was capable of producing thin but strong metal sheets at a reasonable cost. Most lath in the 1880s & 1890s was perforated which the Washington County Courthouse metal lath definitely is. In 1894 the magazine the American Architect and Building News discussed the two kinds of commercially available metal lath.[2] One was a 16 gauge wire mesh-a type precursor to modern expanded metal lath- and the other was “26 gauge metal crimped-up… or corrugated (Cincinnati Corrugating Company’s), with a series of perforations to make a clinch for the plaster”.

In their 1888 catalogue the Cincinnati Corrugating Company stated “We have patrons in every state and territory, and from Canada to Mexico inclusive.” Assuming this was not hyperbole, that would mean their products were in use in Mississippi. They also stated that at that time their metal lath was being used extensively in government buildings, which it might not be a big surprise that the Washington County Courthouse is one of those. While the Cincinnati Corrugating Company did not have a monopoly on perforated metal lath manufacturing, they were seen as innovators due to using corrugated iron stock. The corrigation had two benefits; acting as furring and to impart additional stiffness to the lath. The corrugation acting as furring gave space between the lath and the studs along with allowing for “ample rest for the plaster”. The strength from corrugation allowed for thinner , less weighty iron sheet stock to be used. [3]

Metal laths would soon be exalted not only for their fire preventive-ness but also for the ease & speed of installation and low-cost vs. wood lath. Expanded metal lath was well-known to architects by 1896,[4] and its installation was such a major industry by 1899 it necessatated the establishment of the Wood, Wire and Metal Lathers’ International Union. By the 1910’s expanded metal lath was the industry norm as seen in the plethora of manufactures examples in the 1914 Metal Lath Hand-Book.[5]

So to conclude with the answer to our Washing County Courthouse metal lath question; what it looks like happened in the courthouse is that the perforated corrugated metal lath was the original and there was a cove to the ceiling in 1891. The 1891 ceiling and cove were ditched in 1930, but the 1891 flat wall plaster was kept in place.

While perforated lath would continue to be used later on in the 20th century, it was only when a very rigid back was needed say as a backing for tile.[6] Though old method and materials always hang on (and without seeing the building in person) I would wager to say that the lath we see would date closer to 1891 than 1930. Since we all cannot go see this attic space in person its great we have the MDAH HRI database sharing these images with the world. Did this lath-ing matter test your metal?

1 McDonald, Marylee. United States. National Park Service. Preservation Brief 21: Repairing Historic Flat Plaster Walls and Ceilings.. Washington DC: , 1989. Print.

2 Hill, George. “Slow Burning Construction.” American Architect and Building News. 21 04 1894: 28. Print.

3 “Iron Lath.” Catalogue of the Cincinnati Corrugating Company. Nov 1888: 19. Print.

4 Kidder, Frank Eugene. Building Construction and Superintendence, Vol. 1. 1896. Print.

5 McMaster, H.B. Associated Metal Lath Manufactures. Metal Lath Hand-Book Youngstown Ohio:, December 1914. Print.

6 Concrete Steel Company of New York. Havemeyer bars & building products. New York:, 1925. 30. Print.

Categories: Architectural Research, Courthouses, Greenville, Historic Preservation

simply look at the nails—-if round, it was installed after 1906 and if square nails were used, it was installed 1906 or before give or take a year or two for supplies to exhaust or be replaced

LikeLike

What is your theory behind the date 1906? Cut or “square” nails were significantly faded by 1890 thanks in part to the “Great Nail Strike” from May 1885 to June 1886. Wire or “round” nails flooded the market due to the lack of cut nails caused by the strike. Manufacturing of cut nails sharply declined after the strike ended in 1886, because wire nails were found to be cheaper to produce and easier to use.

Period instructions for installation do not indicated that nails were used to hold metal lath to framing, but rather staples and wire. The April 24, 1894 American Architect and Building News article states metal lath should be attached “to wooden beams with galvanized staples, secured to the framing by being bent around it, if for iron beam-flange protection, or secured to the framing with galvanized wire where necessary.” In the photographs we can see clear use of wire to secure the metal lath to metal straps.

Unless I get to see it in person I could not say more. Like I said earlier only through the magic of the internet and the MDAH HRI database do we get to see this cool space.

LikeLike

i am sure you know more than the rest of but according to blacksmith association readings and articles and the victorian houses i have restored, the first decade of the 1900’s pretty well shows cessation of the use of square nails as it was so much cheaper to make “wire” nails , which, incidentally, have only a fraction of the anchoring strength of square nails as demonstrated by their continued use by farriers and floorers.

LikeLike

That make sense because a black smith would not make wire nails as that is a mechanized process. A black smith producing forged nails by 1900 would have been fairly antiquated as it is such a labor intensive process. Cut nails are also still used in masonry but they are obviously machine made.

Thank you for the tip on the black smith publications. Do you have any of the information on those smithing publications? I would be interesting in checking them out and learning more.

LikeLike

Your 1906 date coincides with my experience. While the development of wire nails–as I recall–was a couple decades earlier, yet I have noted in the houses that I have examined that they didn’t come into common use until much later. So based on the houses that I have examined–most of which I couldn’t date to the precise year–I had settled on a ca 1900 date, which is pretty much the same as your 1906.

LikeLike

The most recent publications Ive seen that touches on this matter are the Finishes Analysis and the Historic Structure Report of the Charnley-Norwood House in Ocean Springs. Both the reports and a physical inspection of the 1897 building show that cut nails were used for the framing and for applying the shingle siding. Wire nails were used for all the trim and interior work. I don’t want to come across as saying the use of cut nails were passe by c. 1900 but they were quickly falling out of use.

LikeLike

What’s in those boxes? The county records I can’t find?!!!

LikeLike

I am not sure about the boxes, but there a lot of circuit court docket books stored up there.

LikeLike

I see more on the MDAH database http://www.apps.mdah.ms.gov/Public/prop.aspx?id=29587&x=1616&y=1050&bg=white&view=photos&DateTaken=1-13-2014

LikeLike

I can’t say. Ive only been to the Washington County Courthouse through the magic of the internet and the MDAH HRI database.

LikeLike

Those old record books are still up there and they are probably the ones I need to look at for some research I am doing. I really wished the courthouse would handle the old records better than they do. Those records have survived since 1827 when the county was formed and also survived the Civil War thanks to Martin Marble hiding them from the Union Army. I need to plan another trip up soon.

LikeLike

Very interesting because I always thought of metal lath as being a newer innovation. My 1925 house in Vicksburg has early-vintage perforated (round holes) sheet rock on the studs. Plaster was laid on top of this sheet-rock, and the wet plaster oozed into the holes to support the mass. But a 1949 renovation in one room (the “new” bathroom) used metal lath as the support.

LikeLike

Ah you have rock lath. Very cool. Here is a link to an article I wrote about some rock lath on the coast. 1925 would be pretty early on in the manufacturing of rock lath.

https://misspreservation.com/2012/04/19/the-real-rock-lath-of-jackson-county/

There was a time when wood and expanded metal laths were used together. The wood lath was used for most of the wall as it prevented flexure and the wire lath was used at the corners. Expanded metal lath has to have a Portland cement plaster (or a high Portland content in gypsum plaster)used. As you can imagine the metal used for expanded metal lath is very thin and could flex a great deal. Without being essentially encapsulated in the very hard Portland plaster the expanded metal lath could flex causing the plaster wall to crack.

LikeLike

Princella Nowell of Greenville asked me to submit the following comment/ query. She is a native of Washington County and a noted local historian:

So you guys have found my hang out or “fortress of solitude”. Will have to think on lath question, but I have two questions I would like answered…

1. During the 1927 flood the original courthouse tower was still there. I have not found any record of when it was remodeled. I asked why it was changed and was told it was like living in a barn with the door open (so 19th century). When this was done is one of my long unanswered questions. Frank Carlton told me stories of he and other boys who were paid to capture and kill the pigeons in the tower. Once he stepped through the roof. I have visited inside the upper present day truncated tower.

2. This question takes a little more creativity to answer and to me is more interesting than lathing. Although the building looks imposing out side. It is only two story. The whole of the rest is attic. One large room except for the tower base. In the north wall of the tower base is a large louvre. I am wondering if this louvre is how they cooled the courthouse by adjusting it to draw a breeze up the tower? Has any one ever heard of such? Could it work?

Lastly. You have to “leap” in and out of the attic. The room outside the attic is used for storage. I am told this was the balcony (the floor has a theater slope) where the African Americans sat. Today a wall divides it from the courtroom. Maybe this was done at the time of the lathing. If memory serves the seats are still in there though they are no longer attached.

Lastly again (for the record)I have been on the roof of the courthouse but I have never gotten up my nerve to go up the staircase to the outside through the attic.

Princella

LikeLike

Princella, I had been operating under the assumption that the tower was capped during the 1930 renovation under James Spain. If not then, perhaps during the Depression, when federal work programs were responsible for this treatment on a number of courthouses around the state (see Copiah County Courthouse dome); but since there is no plaque for a federal project on the building, I had assumed it was the 1930 renovation. Do we have any evidence that it was still in place after the 1930 renovation?

LikeLike

Jennifer, in the main hall is a plaque with info on Spain’s renovation. I think I used it to go to Board of Supervisors minutes. It has been some time ago. All I found were some general renovation and electrical improvement notes. No mention of the tower work. I’ve also checked newspaper and didn’t find any mention of tower work. Interviews have brought forth no history. Photos from 1927 show as still in tact.

In the last few months the courthouse has gotten a new roof. A perimiter was set up by the company working on it and i was not able to use my X-ray vision (see earlier refrence to Fortress of Solitude) to look into the area at base of courthouse on west side. I informed one of the supervisors twice that there was a stack of keystones piled along the courthouse that were from tops of the windows of the previous jail and he should be aware so that the contractor did not remove them on clean up. To be honest I haven’t gone back to check them and don’t know if he even thought about it after my call.

The books in the tower used to be well placed on shelves. Over time the shelves have fallen and it is sort if a mess up there. The good thing is they are dry and away from any one’s legs. I do so worry about them “walking”. There have been two great courthouse clean outs in the past where books were thrown out. These are mostly chattel books and common law books. Some are hand written but not needed for reference by lawyers today. Is there any way we can protect them? Away from sight they have been fine. Downstairs they take up needed space.

LikeLike